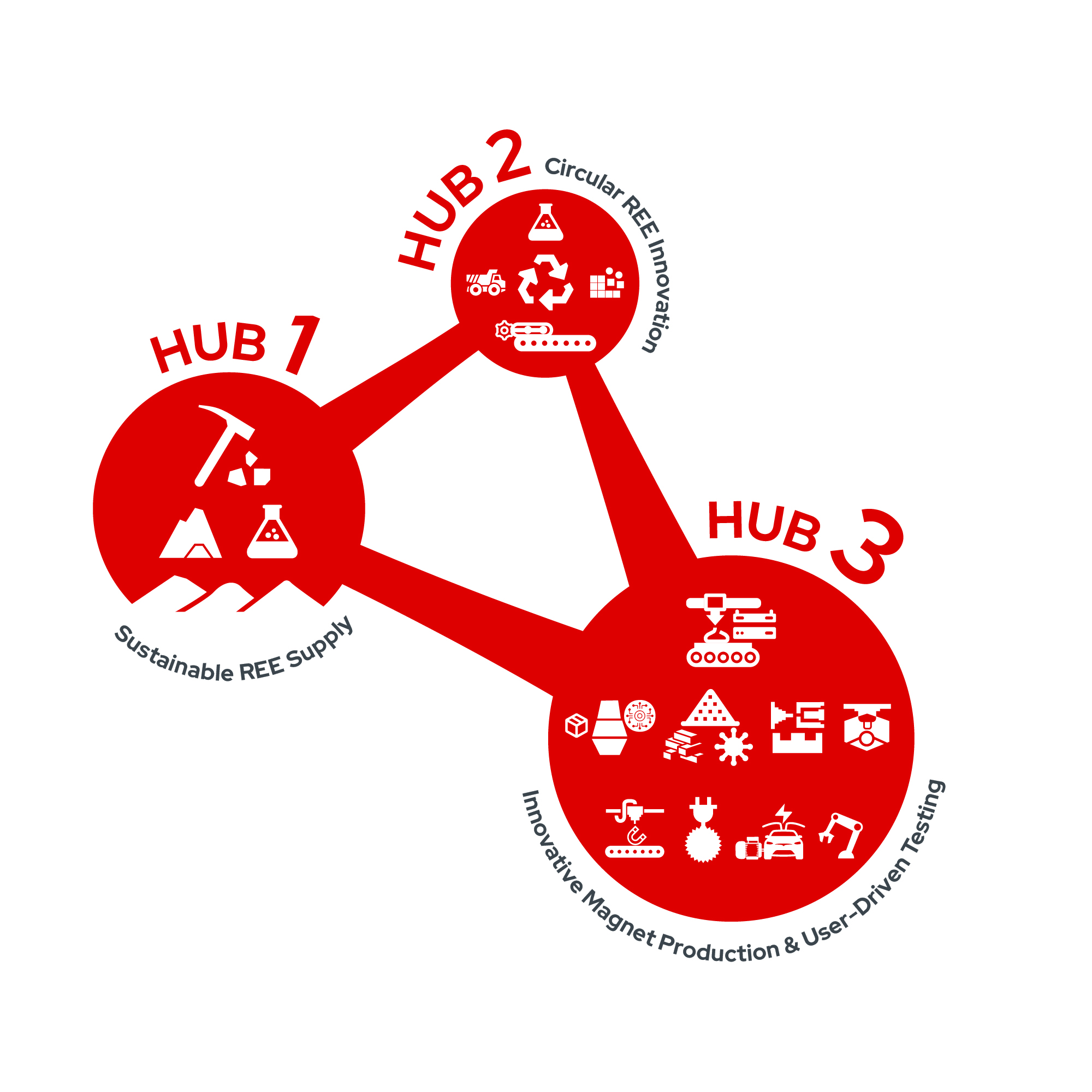

Sustainable REE Supply Hub

This Hub focuses on developing eco-friendly methods to extract REEs from mining and tailings, ensuring a secure supply of raw materials within the EU. The innovations developed will cover the production and refinement of REE from standard and non-conventional deposits. At their core will be the processing and refining methods for the production of REE from monazite concentrates and the production of REE concentrate from iron ore. It will be complemented by the demonstration of 2 fully scalable hydrometallurgical processes for the efficient and green production REE’s carbonate and REE’s oxides from concentrates from miscellaneous mining sources.

Circular REE Innovation Hub

This Hub will structure and demonstrate Circular PM technologies across various waste streams (incl. EV/WEEE). Strategic activities will focus on the consolidation of waste streams through a dedicated marketplace for WEEE. Dedicated tools (dismantling protocols, safety guidance, etc.) will be developed for the entire industry. Leading-edge Innovations will be implemented at each step, including innovative collection, multiclass sorting, modular disassembly and pre-treatment, hydrogen decrepitation (short loop) and two hydrometallurgical processes (long-loop) that shall shape top-quality precursors.

Innovative Magnet Production & User-Driven Testing Hub

This Hub will demonstrate a series of Innovations in the field of Magnet production and User Testing, including two innovative and scalable oxide reduction processes (green reduction and sublimation), two Pilots for flake production from scraps and gas atomization from standard and wire filament to complement other powder preparation routes, three efficient PM Tech Production Lines on innovative Sintering, Bonding and Hybrid Printing manufacturing processes. The resulting PM will be tested and validated by end-users in automotive, industry and energy applications.